Equipment Integration Technology

1.Small-scale Universal Modularized LNG Train

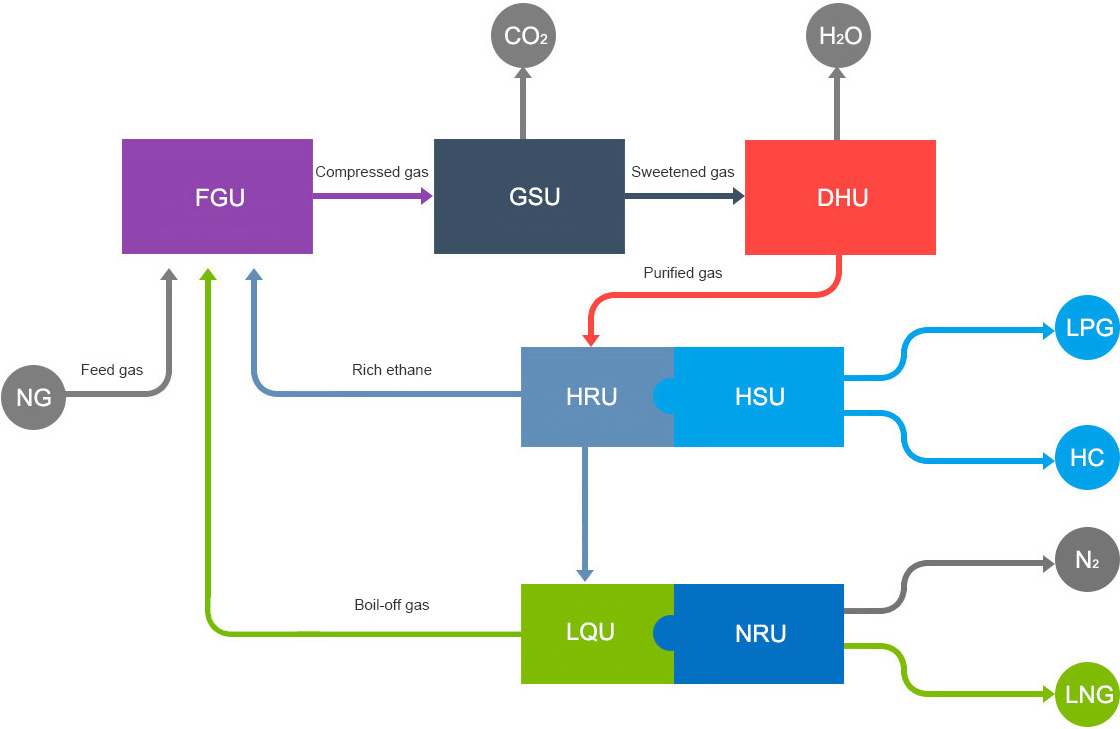

The Small-scale Universal Modularized LNG Train is developed based on the existing core technology of natural gas liquefaction, which separates the traditional natural gas liquefaction process into various individual functional modules and proceeds with skid-mounted design and manufacturing for the natural gas liquefaction plant.

Technical features, major technical performance or product functions:

Technical Features:

It can match an entire liquefaction train by adding /removing or substituting the modules based on the different requirements and various gas qualities (coal bed methane/ pipeline gas/ biomass gas, etc.). It can also provide a single modularized unit product to meet customer needs quickly and provide solution for LNG liquefaction market.

Technical Parameters:

S30K:30000Nm³/d

S60K:60000Nm³/d

S100K:100000Nm³/d

S150K:150000Nm³/d

So far, Xindi has built a demonstration plant and three single units (heavy ends removal unit) which have been operated in Zhenlai and Langfang Haida.

2.Equipment Standardization and Modularization Integration Technology

It can quickly realize the technology industrialization for the internal various processes technologies and external technologies via the technology of development, design and manufacturing which are standardized and modularized by the Equipment Integration.

Technical Features:

With international advanced modularization concept, mature module division principle and standar modularization design ideas, it can perform standarization & modularization development and design for the process and realize the industrialization of the technology.

2) With integrated design, procurement and integration technology, it can realize factory-like manufacturing for the plant, which has improved the quality and shortened the construction period. This technology has applied in the projects of COG to LNG, NG liquefaction and THE hazardous waste treatment by ENN Research Institute, which has accelerated the industrialization and market development process of the technology.

3.Skid-mounted L-CNG filling unit

Xindi skid-mounted L-CNG filling unit can fill the vehicle through LNG boosting gasification and it can also directly fill liquid to vehicle, which applies in multi-functional LNG filling station.

Technical features, major technical performance or product functions:

1) Integrating various equipments such as unloading, tank pressure regulating, CNG filling, LNG filling on the skid with functions for filling both LNG and CNG vehicle.

2) With the automatic temperature switch device, the electric heater can be switched according to the temperature, which greatly reduces electricity consumption and is safe & energy-saving. The demonstration unit has been assembled and run smoothly at the Langfang test site.

4.Skid-mounted CNG filling unit (one-skid-with-two-compressor type)

The one-skid-with-two-compressor CNG filling unit--two compressors integrated within one skid with sharing one dehydration unit and control system--has been developed on the basis of market demand, which can enrich CNG filling unit product category, offer more options for clients and meet the requirements of one run/one standby or both compressors run at the same time.

Technical features, major technical performance or product functions:

One skid-mounted CNG filling unit is equiped with two compressors. Both compressors can run simultaneously, which has the capacity of over 1,500Nm3/h, better performance and smaller footprint. It can also operate as one run & one standby to avoid shutdown of the station.

Such unit has been successfully operated in Xinghua of Jiangsu, Chengyang of Qingdao, Huaiyin of Jiangsu, Shijiazhuang, etc.

5.LNG filling unit

The LNG filling unit developed by Xindi is modular design and manufacture with function segregation, which can design serialization products as per consumer needs.

Technical features, major technical performance or product functions:

The unit integrates the systems such as small storage tank, booster, vaporizer, pressure regulating, heating, metering, odorizing, leakage alarm, remote control and so on into one skid, it realizes an integration and split type skid layout, serialization design and whole coverage, which can meet the requirements for different customers.

The unit has already been successfully operated in Shangqi 600Nm³/h single-point direct supply project, Suining ENN 500Nm³/h single-point direct supply project, Zhucheng ENN 500Nm³/h single-point direct supply project, etc.

6.Skid-mounted loading arm

The skid-mounted loading arm realizes modular production, standardization design and manufacture according to the technological process of the liquefaction plant and LNG receiving terminal and station design conditions.

Technical features, major technical performance or product functions:

The loading arm device is developed with functionalization and standardized design, and the design and equipment selection for loading arm device can be performed based on the requirements of different users, It can perform ration loading and non-ration loading, which is suitable for various loading conditions.

The first generation product has been applied in the 20,000Nm³/h COG to LNG project. The updated second generation product, under the process of design and manufacture, will be used in the Zhoushan project.