To be an technological innovative excellent enterprise in the fields of energy clean utilization and energy-saving & environment protection.

Innovate green energy engineering ,Improve the quality of human life

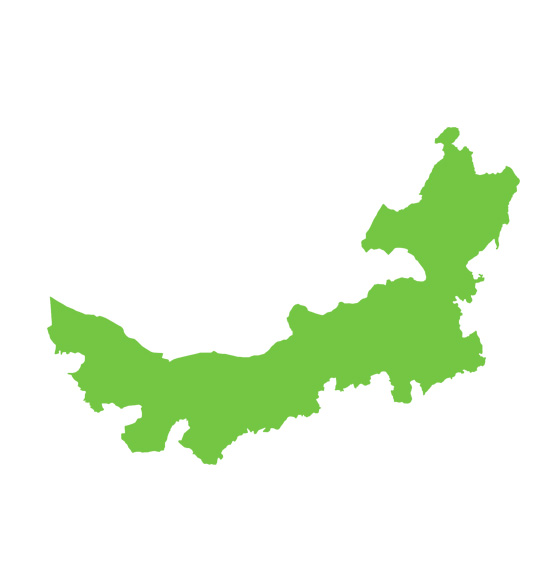

CNPC Hainan LNG Depot Project

It is the first small LNG receiving terminal in China that adopts the proprietary technologies and domestic equipment.

The annual turnover of the project is 3 million m3 (about 1.32 million ton) .

The total capacity of the LNG storage tanks is 200,000 m3

This project is located in Chengmai County, Hainan Province. Xindi independently accomplished the whole process of engineering design, procurement, construction, commissioning and start-up. The project has been put into operation in 2014. The LNG receiving terminal system recovers BOG gas through ambient temperature compressors, which reduces cost and the equipment procurement period. It fills the gap of applying ambient temperature compressor in the LNG receiving terminal at home and abroad, and has obtained two national patent certificates.

Huludao Qinshen Line Natural Gas Pipeline Utilization Project

Pipe diameter: DN600

Length: 14.7km

Design pressure: 4.4MPa

Huludao Project Department Tel: +86-429-3122674

Beijing Yanhua 3rd Power Plant 220 t/h CWS Boiler Exhaust Denitration Project

Microalgae Carbon Fixation Bio-Energy Industrialization Demonstration Project

Wuhai Huaxin COG to LNG Project

Project Capacity: 240 Million Nm3/a

Contracting type: EPC

Wulanchabu Underground Coal Gasification 20kt/Year Methanol Pilot Project

Hegang Zhengnan COG to LNG Project

Project Capacity: 264 Million Nm3/a

Contracting type: E

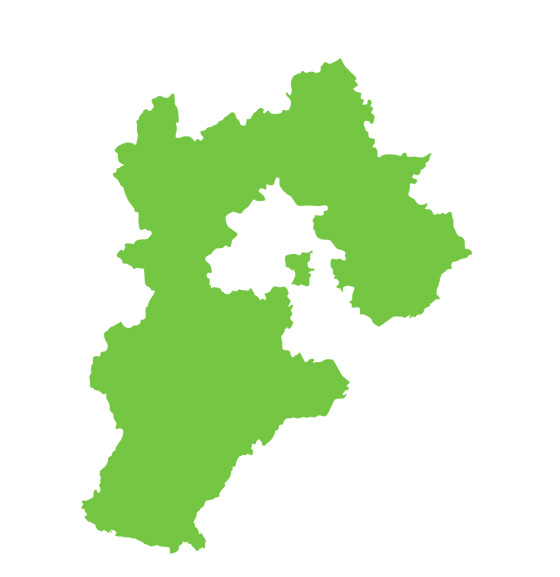

South-to-North Water Diversion Bazhou Auxiliary Project - Hebei Shengfang Water Treatment Plant and Water Distribution Pipeline Project

Water treatment capacity is 80,000m3/d and in the long term plan it is 100,000m3/d. The area for the production and office use in the plant is 12,500m2. There are 30 water tanks of various volumes and the water storage capacity is 28,000m3.

The water from the South-to-North water diversion project has met the drinking water standards via dosing in front of filtering, mechanical mixing, mesh flocculation, inclind pipe deposite, V type filter cistern, dosing after filtering, etc. When the project is completed, it will effectively improve the quality of drinking water and local people can drink the clean, hygiene and safe Yangtze River water.

CNPC Hebei Huaqi - Bazhou Kangxianzhuang LNG Project

Treatment capacity: 1 Million Nm3/d

Located at Kangxianzhuang, Bazhou City, the project consists a 20,000 Nm3 LNG storage tank, a filling station with 6 loading arms, associated utilities, substation and power distribution station. By using a leading MRC and liquefaction technology, it greatly reduces the customer’s operation and maintenance cost.

The project was successfully put into production in March 2013.

Jiantao (Hebei) Chemical Co., Ltd. 100,000Nm3/h Coke Oven Flue Gas Comprehensive Utilization Project (First Phase)

Huabei Oilfield Renqiu LNG Project

Treatment capacity:100,000 Nm3/d

Thangshan Tangsteel COG to LNG Project

Annual COG treatment capacity: 320 Million Nm3

Annual LNG capacity: 173,600,000Nm3

High purity hydrogen extraction: 16 Million Nm3/a

The project is located at Luanxian County Industrial Zone, Hebei Province. It uses advanced technologies independently developed by Xindi, such as COG purification, methanation, MRC liquefaction, low temperature fractionation, and carbon addition to improve methane production and PSA to extract hydrogen.

The project was successfully put into operation in August 2014.

Qinhuangdao Anfeng Steel Co., Ltd. COG to LNG Project

Treatment capacity: 880 Million Nm3/a

Contracting type: E

Bazhou-Baoding Natural Gas Pipeline project

Pipe Diameter: D300

Length: 94.9km

Design Pressure: 6.3MPa

Langfang project department telephone: +86-316-2691275

Liaocheng project department telephone: +86-635-6961989

Huangdao project department telephone: +86-532-86888186

Huangdao (Jiaonan) project department telephone: +86-532-89053351

Jiaozhou project department telephone: +86-532-82212960

Rizhao project department telephone: +86-633-3388028

Chengyang project department telephone: +86-532-87966290

Zhucheng project department telephone: +86-536-6539998

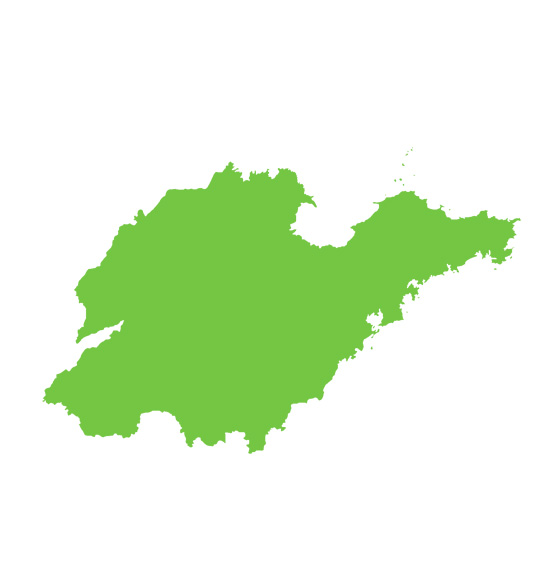

Field: COG to LNG Project

Project Name: Shandong Weijiao COG to LNG Project

Capacity: 560 Million Nm3/a

Contracting type: E

Anqiu-Zhucheng Natural Gas Long Distance Pipeline EPC Project

Pipe Diameter: D457

Length: 60km

Design Pressure: 4.0MPa

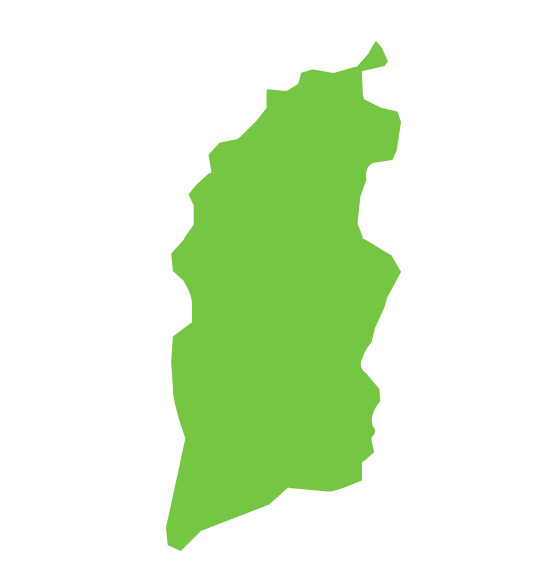

2nd Phase of Shanxi Qinshui ENN Coal Bed Methane Liquefaction Project

Treatment capacity: 300,000 Nm3/d

Shanxi Yangcheng Shuntianda CBM Liquefaction Plant

Treatment capacity: 300,000 Nm3/d

Shanxi Gas Linxian CBM Liquefaction Project

Treatment capacity: 1,200,000 Nm3/d

Shanxi Longhui COG to LNG Project

Project Capacity: 184 Million Nm3/a

Contracting type: EPC

Shanxi Huayang COG to LNG Project

Project Capacity: 270 Million Nm3/a

Contracting type: EPC

Shaanxi Beiqiang COG to LNG Project

Project Capacity: 360 Million Nm3/a

Contracting type: EPC

Henan Jingbao COG to LNG Project

Annual COG treatment capacity: 240 Million Nm3

Annual LNG capacity: 95 Million Nm3

The project is located at Pingdingshan City, Henan Province. Xindi provides complete process package, design and installation service, as well as the independently developed technologies such as COG purification, methanation, liquefaction and separation process. LNG production by using the COG produced during the coking production process not only improves the comprehensive utilization of COG, but also effectively reduces the customer’s investment and operating cost.

The project was successfully put into production in May 2013 at one go and has been working smoothly since then. It has achieved the design LNG capacity of 300,000m3/day and has become the model project for its long term, full load and safe operation.

Xin’an Yushan Coal Mine Coal Well-type Gasification Coal Mining Pilot Project

Kaifeng project department telephone: +86-371-22992161

Shangqiu project department telephone: +86-370-6086809

Xinxiang project department telephone: +86-373-3069237

Nanjing Industrial Park Supercritical Oxidation Industrial Solid Waste Treatment Project

Nantong Zhengtuo Gas Co., Ltd. 6,500Nm³/h Industrial Waste Gas Regeneration Comprehensive Utilization Project

Huaian project department telephone: +86-517-83991693

Lianyungang project department telephone: +86-518-85154162

West to East Gas Pipeline “Baoying-Dafeng Port”Natural Gas Branch Pipeline (Terminal: Yancheng)

Pipe Diameter: DN300

Length: 135km

Design Pressure: 6.3MPa

Yancheng project department telephone: +86-518-85154162

Taixing project department telephone: +86-523-87665750

West to East Gas Pipeline “Baoying-Dafeng Port”Natural Gas Branch Pipeline (Start from Yangzhou)

Pipe Diameter: DN300

Length: 135km

Design Pressure: 6.3MPa

Bengbu project department telephone: +86-552-4045702

Chaohu project department telephone: +86-551-82856759

Lu’an project department telephone: +86-564-3365750

Chuzhou project department telephone: +86-550-3078276

Bozhou project department telephone: +86-558-5533395

Dingyuan-Fengyang High Pressure Gas Pipeline Project

Pipe Diameter: D508

Length: 186km

Design Pressure: 6.0MPa

Zhejiang Zhoushan LNG receiving terminal and filling station project

The annual designed LNG turnover for the first phase is 3 million tons, and the total annual turnover will be 10 million tons.

It can realize the entire LNG process operation such as LNG receiving, storage, gasification, ship loading, truck loading,etc.

Three jetties for unloading, loading and roll-on roll-off vessel can perform loading/unloading simultaneously.

The integrated cold energy utilization technology combining with power generation, ice-making and air conditioning from cold energy.

The main vaporizer and sea water circulating pump are all domestic equipment, which has improved the localization rate of main equipment.

Xindi independently accomplished the whole process of engineering design, procurement, construction, commissioning and start-up. The project aims at a LNG filling base for international vessels combining with the clean energy demand for the sustainable development in Zhoushan Islands and new district in future, also, it can work as a natural gas reserve for the emergency and peak-shaving in Zhejiang Province. It will become one of the receiving terminals with the largest capacity and most complete functions in China.

It is expected in operation in 2018.

Haining Nanbei Avenue/Jianshan New District Sub-High Pressure Natural Gas Pipeline

Pipe Diameter: DN350

Length: 25Km

Design Pressure: 0.8MPa

Zhuzhou project department telephone: +86-731-28835328

Xiangtan project department telephone:+86-731-52255151

Huaihua project department telephone: +86-745-2655253

Xingsha Storage & Distribution General Contracting Project for Hunan ENN Changsha Natural Gas Utilization Engineering

Treatment capacity:200,000 Nm3/d

Quanzhou project department telephone: +86-595-22003085

Hui’an project department telephone: +86-595-87800330

Nan’an project department telephone: +86-595-86921157

Sinopec Maoming Branch High Sulfur Coking Coal CFB Boiler Attaching with FGD Unit Project

Dongguan High Pressure Pipeline

Pipe Diameter: DN610

Length: 210Km

Design Pressure: 4.4MPa

Zhaoqing project department telephone: +86-758-2799860

Huadu project department telephone: +86-20-29892772

Guilin project department telephone: +86-773-3559369

Beihai ENN Weizhou Island LNG Project

Treatment capacity: 250,000 Nm3/d

Qujing Yuntou COG to LNG Project

Project Capacity: 184 Million Nm3/a

Contracting type: EPC

Xindi Energy Engineering