Energy-Saving & Environment Protection

1.Hazardous waste treatment technology

a.Supercritical waste treatment device prizing technology

Based on ENN’s supercritical hazardous waste treatment technology, Xindi has made standardized, skid-mounted design and manufacturing for this treatment unit, which has formed a highly-integrated product combining with process, autocontrol, electronical technology, standardization and modularization.

Technical features and major technical performance:

1) Based on the harmless, minimization, and recycling realized by the hazardous treatment system emission, it realizes the factory-like engineering for construction project, which has improved the project quality, shortened the construction period and labour intensity, and realize the reutilization by moving the treatment unit.

2)Speed up the construction progress, realize equipment integration and save land resources.

The technology has been applied in the expansion project of Langfang ENNEW Sludge Treatment Co., Ltd. and the Nanjing ENN Environment Protection Supercritical Oxidation Treatment Industrial Solid Waste Project.

b.Sludge supercritical water treatment technology

Making use of the features of supercritical water and take it as the media, the organic matters in sludge can be completely oxidized the into clean matters such as H2O, CO and N2 through adding oxidizing agent. S,P and so on are turned into highest valence salt stabilization, heavy metal oxidization stabilization solid phase exists in the ash content; no secondary pollution caused by SOX, NOX and dioxins.

With Xindi’s supercritical sludge treatment technology, the organic matter conversion rate is over 99% and the volume reduction rate is above 90% and the output water is clean, which can reach China’s First Class effluent standard. The oxidative products are clean and no pollution; neither toxic gas such as SOX, NOX and dioxins nor PM2.5 and PM10 are generated. It will not pollute the soil and underground water, which can solve the sludge pollution and land resource occupation problem fundamentally.

This technology has been employed for LangFang 240 ton supercritical sludge treatment project successfully.

2.Pressure energy utilization technology

Natural gas gate station, pressure regulating station and so on can generate great amount of pressure energy when regulating. Such pressure energy can be recovered with technological means for LNG production, power generation, ice-making, etc., which has realized energy recycling.

Technical features, major technical performance or product functions:

1)It uses expander technology to realize energy transformation and liquefies part of natural gas into LNG, which can be used as city peak shaving gas source and makeup gas source for LNG filling station. It features low investment, less rotating equipment and low cost.

2)It uses expander power generation technology to turn pressure energy into electric energy with the advantages of short cycle, smaller footprint, quick investment recovery, smooth operation,etc.

The pressure energy liquefaction technology has bee applied in Luoyang Litun Project; and the pressure energy power generation technology is being applied at the Gate Station at south of Langfang City.

3.Biomass resources development and utilization technology

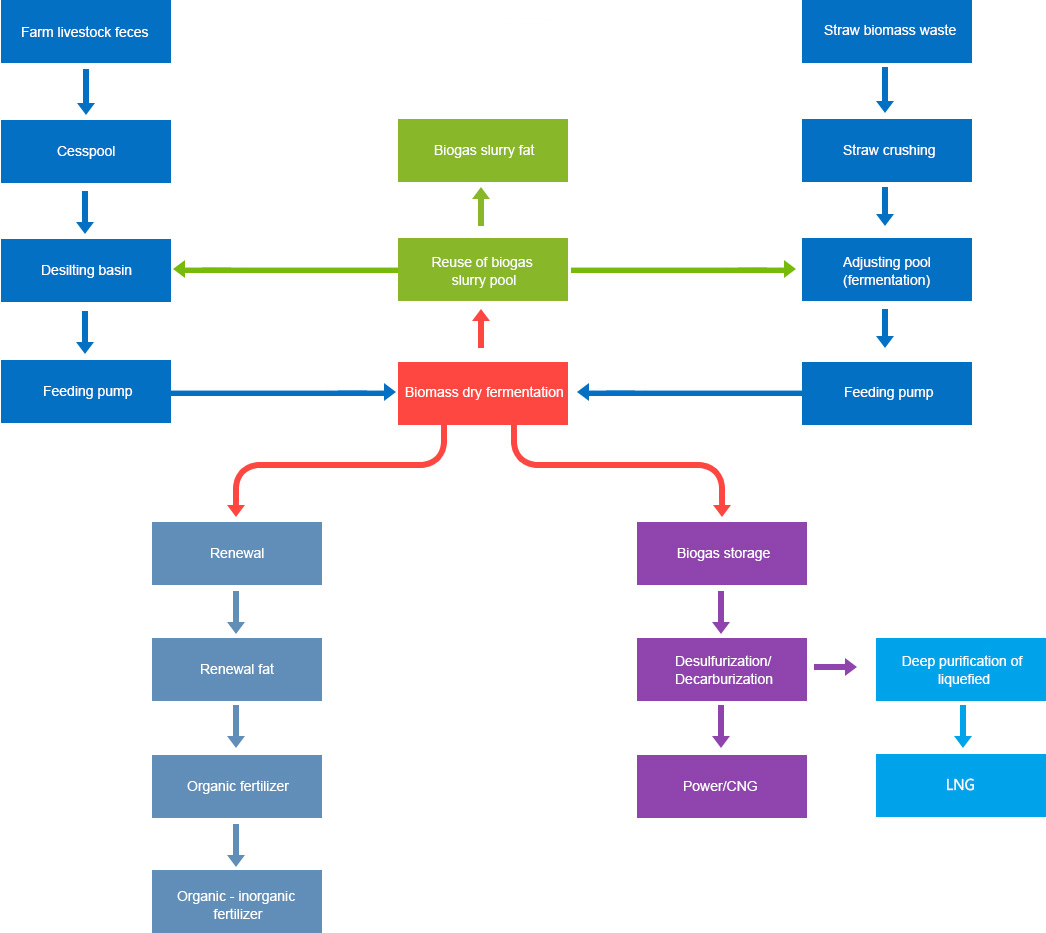

It uses straws, livestock manure and kitchen garbage as raw materials and generates natural gas via purification with biogas extraction technology, which is the development direction for regional distributed energy in rural areas and has positive effect for new rural construction and solving environment-pollution problem.

Technical features, major technical performance or product functions:

With medium temperature drying large-scale fermentation technology and highly-efficient fermentor, it generates high purity natural gas through purification technology. The waste residue will be deeply processed into organic fertilizer, which makes the organic waste into high quality energy and fertilizer by recycling.

The technology has been applied in the Nantong Zhengtuo Biogas Project. It has won the First Prize of Excellent Consultation Award and Second Prize of Excellent Design Award in Hebei Province.

4.Centralized heating with industrial waste heat recovery

The technology can be used for urban heating to by utilizing the residual heat in the industrial circulating water via thermal-distributing & heat exchange technology. It not only realizes the utilization of residual heat, reduces environment pollution caused by fossil fuel-based centralized heating, but also reduces the temperature of the circulating water.

Technical features and major technical performance:

1)It provides heating for urban area by extracting the heat in the low quality circulating water with heat pump technology, which is low energy consumption, high efficiency and no pollution.

2)It uses distributed variable-frequency secondary pump technology to optimize the power distribution for system water circulation; the variable-frequency pump regulates the operation flow rate in every pump station to ensure the balanced regulation in the pipeline network, which can save huge thermal energy and electric energy.

This technology has been successfully applied in the residual heat utilization project in Shijiazhuang Circulation Chemical Industry Base. The total heat that can be utilized is up to 1,216.8 MW per year. The project won First Prize of Excellent Engineering Consultation Award of Hebei Province in 2012.